About this deal

As adhesives, epoxies bond in three ways: a) Mechanically, because the bonding surfaces are roughened; b) by proximity, because the cured resins are physically so close to the bonding surfaces that they are hard to separate; c) ionically, because the epoxy resins form ionic bonds at an atomic level with the bonding surfaces. This last is substantially the strongest of the three. [51] By contrast, polyester resins can only bond using the first two of these, which greatly reduces their utility as adhesives and in marine repair.

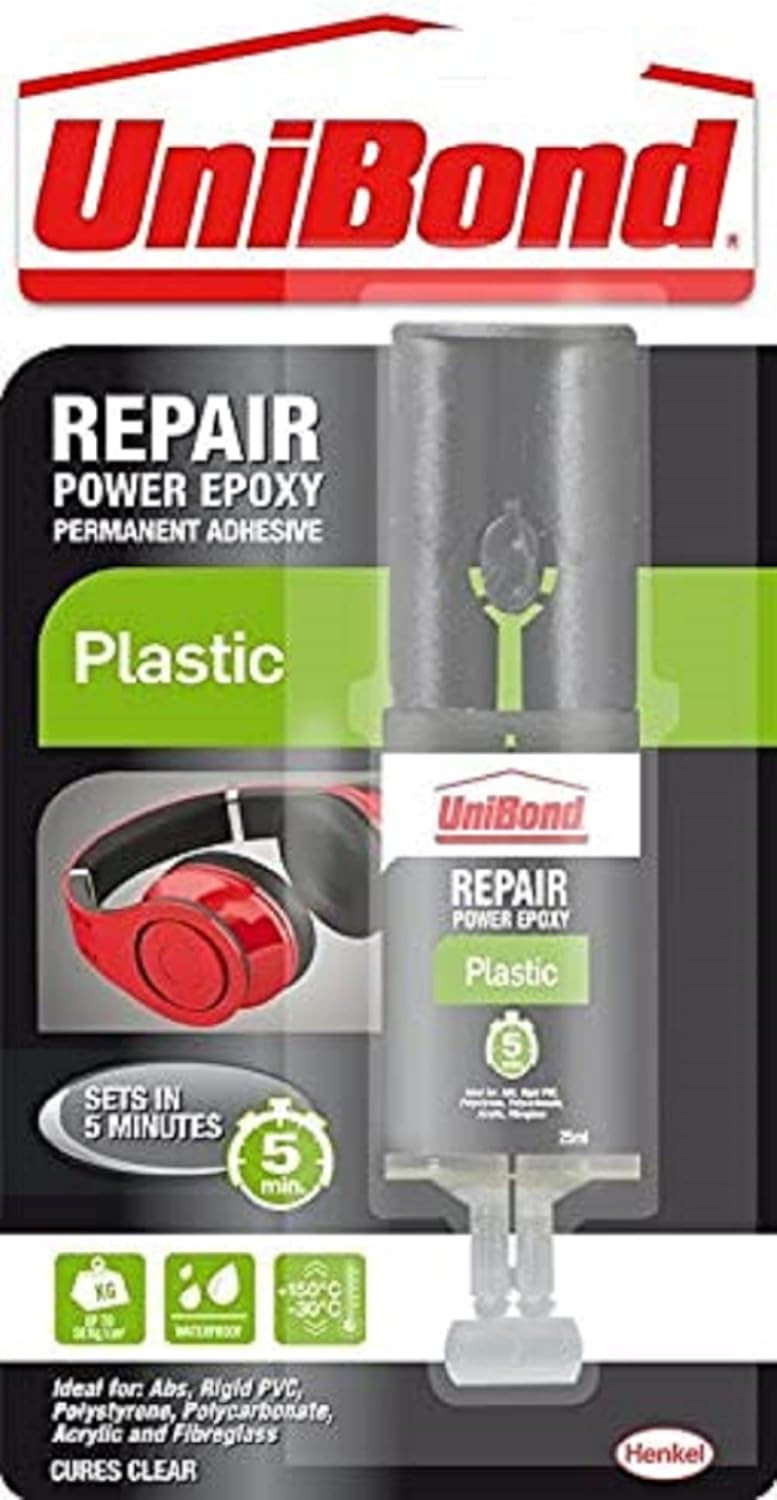

The other production route for epoxy resins is the conversion of aliphatic or cycloaliphatic alkenes with peracids: [13] [14] In contrast to glycidyl-based epoxy resins, this production of such epoxy monomers does not require an acidic hydrogen atom but an aliphatic double bond. US Patent Application for FIRE-RESISTANT GLAZING Patent Application (Application #20130196091 issued August 1, 2013) - Justia Patents Search". patents.justia.com . Retrieved 2022-04-27.The most common epoxy resins are based on reacting epichlorohydrin (ECH) with bisphenol A, resulting in a different chemical substance known as bisphenol A diglycidyl ether (commonly known as BADGE or DGEBA). Bisphenol A-based resins are the most widely commercialised resins but also other bisphenols are analogously reacted with epichlorohydrin, for example Bisphenol F. Epoxy coatings are often used in industrial and automotive applications since they are more heat resistant than latex-based and alkyd-based paints. Epoxy paints tend to deteriorate, known as "chalking out", due to UV exposure. [40] Epoxy coatings have also been used in drinking water applications. [41] Epoxy coatings find much use to protect mild and other steels due to their excellent protective properties. [42] Additionally, it can be used for O-ring bonding. One customer wrote, “ I have used it on virtually every type of hard plastic found in toys, kitchen appliances, fasteners, tools, you name it and never failed to get a strong, long-lasting bond.” Strength:An adhesive with a high tensile strength is very important. A stronger glue will create a more permanent bond between plastics. Epoxy homopolymerisation is often used when there is a requirement for UV curing, since cationic UV catalysts may be employed (e.g. for UV coatings).

Chen, Jie; Nie, Xiaoan; Liu, Zengshe; Mi, Zhen; Zhou, Yonghong (2015-06-01). "Synthesis and Application of Polyepoxide Cardanol Glycidyl Ether as Biobased Polyepoxide Reactive Diluent for Epoxy Resin". ACS Sustainable Chemistry & Engineering. 3 (6): 1164–1171. doi: 10.1021/acssuschemeng.5b00095. Beyond the type of adhesive, buyers should also consider the other various characteristics that make up a glue. The anti-clog metal pin integrated into the cap of the bottle keeps glue fresh to maximize its shelf-life so customers can reuse it over and over again. One reviewer attested, “I bought this 2-3 years ago. Today I grabbed a used bottle from the junk drawer and …the gel glue retained its texture and strength and went on beautifully.” What’s the best glue? Similar to LDPE, Polypropylene has a low surface energy. Some industrial adhesives may be effective, however surface preparation will likely be required. There are several dozen chemicals that can be used to cure epoxy, including amines, imidazoles, anhydrides and photosensitive chemicals. [25] The study of epoxy curing is usually carried out by using Differential scanning calorimetry. [26]Polyphenols, such as bisphenol A or novolacs can react with epoxy resins at elevated temperatures (130–180°C, 266–356°F), normally in the presence of a catalyst. The resulting material has ether linkages and displays higher chemical and oxidation resistance than typically obtained by curing with amines or anhydrides. Since many novolacs are solids, this class of hardeners is often employed for powder coatings. Here at first decide which type of applicator is best for you. Do you want easy dispense or equal dispense? Easy dispense is basically putties and tubes. Whereas equal dispense is syringe containers. Next ask yourself if a resealable cap will help you or not. What’s the best glue? Epoxy, but surfaces must be prepared first by roughening—for example, try using gritty sandpaper. Unnikrishnan, K. P.; Thachil, Eby Thomas (2006-01-01). "Toughening of epoxy resins". Designed Monomers and Polymers. 9 (2): 129–152. doi: 10.1163/156855506776382664. S2CID 137802666.

Many customers successfully used it on their auto bumpers as well. However, it does not work on polyethylene and polypropylene plastics. With a lap shear strength of 600 psi and the ability to resist up to 300°F of intermittent temperatures, this is a durable glue. Another long-term user commented, “Been using this for decades. Easier and safer than electric welding and better than glue. Lasts forever.” Epoxy resins may be thermally cured with anhydrides to create polymers with significant property retention at elevated temperatures for extended periods of time. Reaction and subsequent crosslinking occur only after opening of the anhydride ring, e.g. by secondary hydroxyl groups in the epoxy resin. Homopolymerization may also occur between epoxide and hydroxyl groups. The high latency of anhydride hardeners makes them suitable for processing systems which require addition of mineral fillers prior to curing, e.g. for high voltage electrical insulators. Cure speed may be improved by matching anhydrides with suitable accelerators. For dianhydrides, and to a lesser extent, monoanhydrides, non-stoichiometric, empirical determinations are often used to optimize dosing levels. In some cases, blends of dianhydrides and monoanhydrides can improve metering and mixing with liquid epoxy resins. [31] Phenols [ edit ]In general, uncured epoxy resins have only poor mechanical, chemical and heat resistance properties. [27] However, good properties are obtained by reacting the linear epoxy resin with suitable curatives to form three-dimensional cross-linked thermoset structures. This process is commonly referred to as curing or gelation process. [28] Curing of epoxy resins is an exothermic reaction and in some cases produces sufficient heat to cause thermal degradation if not controlled. [29] Curing does induce residual stress in epoxy systems which have been studied. [30] They may be alleviated with flexibilisers. Sahoo, Sushanta K.; Mohanty, Smita; Nayak, Sanjay K. (2015-01-01). "Synthesis and characterization of bio-based epoxy blends from renewable resource based epoxidized soybean oil as reactive diluent". Chinese Journal of Polymer Science. 33 (1): 137–152. doi: 10.1007/s10118-015-1568-4. ISSN 1439-6203. S2CID 96610298. There are two common types of aliphatic epoxy resins: those obtained by epoxidation of double bonds (cycloaliphatic epoxides and epoxidized vegetable oils) and those formed by reaction with epichlorohydrin (glycidyl ethers and esters). Schulenburg, Jan Olaf; Kramer, Andreas (2004). "Structural Adhesives - Improvements in Vehicle Crash Performance". SAE Transactions. 113: 111–114. ISSN 0096-736X. JSTOR 44699912.

Bal, Kevser; Ünlü, Kerim Can; Acar, Işıl; Güçlü, Gamze (2017-05-01). "Epoxy-based paints from glycolysis products of postconsumer PET bottles: synthesis, wet paint properties and film properties". Journal of Coatings Technology and Research. 14 (3): 747–753. doi: 10.1007/s11998-016-9895-0. ISSN 1935-3804. S2CID 99621770. We hope our review of the best glues for plastic has been helpful. For more suppliers of related products, including tapes, nails, sealants, paints, and sandpaper, consult our additional guides, or visit the Thomas Supplier Discovery Platform. Halogenated epoxy resins are admixed for special properties, in particular brominated and fluorinated epoxy resins are used. [13] Bonding almost instantaneously, the long, tapered, anti-clog nozzle and squeeze release system make for spot-on application, while the fact that it’s a gel rather than a liquid means spillage is almost non-existent. Higher molecular weight diglycidyl ethers (n ≥ 1) are formed by the reaction of the bisphenol A diglycidyl ether formed with further bisphenol A, this is called prepolymerization:Miturska, Izabela; Rudawska, Anna; Müller, Miroslav; Hromasová, Monika (January 2021). "The Influence of Mixing Methods of Epoxy Composition Ingredients on Selected Mechanical Properties of Modified Epoxy Construction Materials". Materials. 14 (2): 411. Bibcode: 2021Mate...14..411M. doi: 10.3390/ma14020411. ISSN 1996-1944. PMC 7830189. PMID 33467604.

Great Deal

Great Deal